Glass Substrate Sensors: The Transparent Technology Powering Next-Gen Detection and Data Accuracy. Discover How This Breakthrough Material Is Transforming Industries from Healthcare to Electronics.

- Introduction to Glass Substrate Sensors

- Key Advantages Over Traditional Sensor Materials

- Core Technologies and Manufacturing Processes

- Applications Across Industries: Healthcare, Electronics, and Beyond

- Performance Metrics: Sensitivity, Durability, and Transparency

- Recent Innovations and Emerging Trends

- Challenges and Limitations in Adoption

- Future Outlook: Market Growth and Research Directions

- Conclusion: The Impact of Glass Substrate Sensors on Modern Sensing

- Sources & References

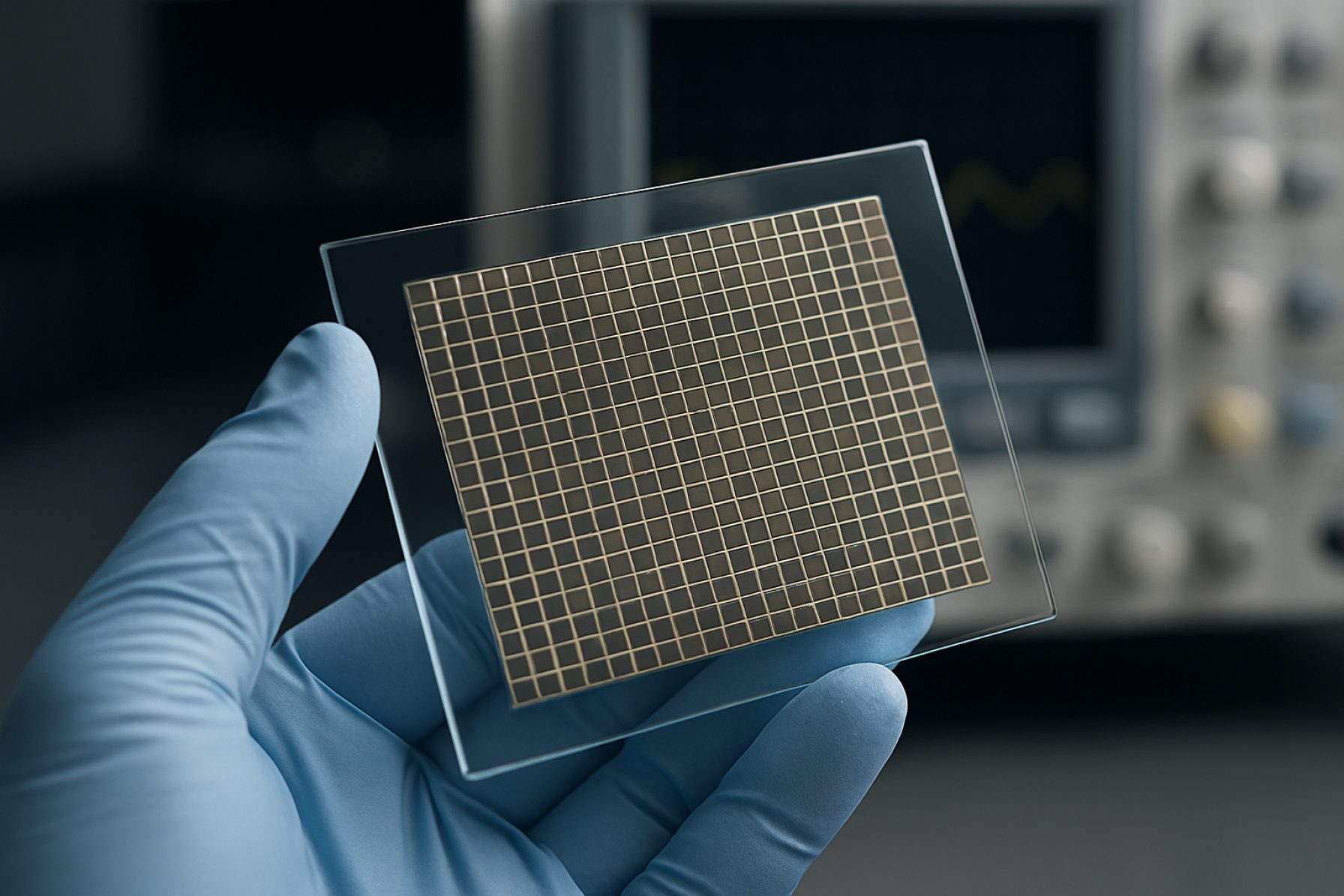

Introduction to Glass Substrate Sensors

Glass substrate sensors represent a critical advancement in the field of sensor technology, leveraging the unique physical and chemical properties of glass to enable high-performance, reliable, and versatile sensing platforms. These sensors utilize glass as the foundational material upon which various sensing elements—such as thin films, nanostructures, or functional coatings—are deposited or integrated. The inherent advantages of glass, including its optical transparency, chemical inertness, thermal stability, and smooth surface morphology, make it an ideal substrate for a wide range of sensor applications, from biosensing and environmental monitoring to microelectromechanical systems (MEMS) and optoelectronic devices.

The use of glass substrates allows for the fabrication of sensors with high sensitivity and specificity, particularly in optical and electrochemical detection schemes. For instance, glass-based platforms are widely employed in surface plasmon resonance (SPR) sensors, lab-on-a-chip devices, and microfluidic systems, where their transparency facilitates real-time optical interrogation and their chemical resistance ensures long-term durability in harsh environments. Additionally, advances in microfabrication and surface modification techniques have enabled the precise patterning and functionalization of glass surfaces, further expanding the capabilities and applications of glass substrate sensors.

As the demand for miniaturized, robust, and multifunctional sensors continues to grow, glass substrate sensors are poised to play an increasingly important role in next-generation analytical and diagnostic technologies. Ongoing research and development efforts are focused on enhancing the integration of glass substrates with novel materials and device architectures, as highlighted by organizations such as the National Institute of Standards and Technology and the Institute of Electrical and Electronics Engineers.

Key Advantages Over Traditional Sensor Materials

Glass substrate sensors offer several key advantages over traditional sensor materials such as silicon, polymers, or ceramics. One of the primary benefits is their exceptional chemical and thermal stability, which allows glass-based sensors to operate reliably in harsh environments, including high temperatures and corrosive atmospheres. This makes them particularly suitable for applications in industrial process monitoring, environmental sensing, and biomedical diagnostics where durability is critical SCHOTT AG.

Another significant advantage is the optical transparency of glass, which enables the integration of optical sensing techniques such as fluorescence, absorbance, and refractive index measurements. This property is especially valuable in biosensors and lab-on-a-chip devices, where real-time, non-invasive optical interrogation is required Corning Incorporated. Additionally, glass substrates exhibit low autofluorescence and minimal background signal, enhancing the sensitivity and accuracy of optical detection methods.

Glass also provides a smooth, inert, and non-porous surface, which facilitates the precise patterning of micro- and nano-scale features using established photolithography and etching techniques. This compatibility with advanced microfabrication processes supports the development of highly miniaturized and integrated sensor platforms Carl Zeiss AG. Furthermore, glass is electrically insulating, reducing the risk of signal interference and cross-talk in electronic sensor arrays.

Collectively, these advantages position glass substrate sensors as a superior choice for next-generation sensing technologies, enabling enhanced performance, reliability, and versatility across a wide range of applications.

Core Technologies and Manufacturing Processes

Glass substrate sensors leverage the unique properties of glass—such as chemical inertness, optical transparency, and thermal stability—to enable high-performance sensing platforms across various applications. The core technologies underlying these sensors often involve microfabrication techniques adapted from the semiconductor industry, including photolithography, thin-film deposition, and etching processes. These methods allow for the precise patterning of conductive, dielectric, or functional layers onto glass substrates, facilitating the integration of microelectrodes, microfluidic channels, or optical waveguides directly onto the glass surface.

A critical aspect of manufacturing glass substrate sensors is the choice of glass type, with borosilicate and fused silica being common due to their low thermal expansion and high chemical resistance. The fabrication process typically begins with substrate cleaning, followed by the deposition of thin films using techniques such as sputtering, evaporation, or chemical vapor deposition. Photolithography is then employed to define sensor geometries, after which wet or dry etching processes are used to remove unwanted material. For applications requiring three-dimensional structures, laser micromachining or precision glass molding may be utilized.

Advancements in bonding technologies, such as anodic or fusion bonding, have enabled the reliable assembly of multilayer glass devices, which is essential for complex sensor architectures like lab-on-a-chip systems. Additionally, the integration of functional nanomaterials—such as graphene or metal nanoparticles—onto glass substrates has further enhanced sensor sensitivity and selectivity. These manufacturing innovations have been instrumental in expanding the application scope of glass substrate sensors in fields ranging from biomedical diagnostics to environmental monitoring (U.S. Department of Energy; Nature Publishing Group).

Applications Across Industries: Healthcare, Electronics, and Beyond

Glass substrate sensors have found widespread applications across diverse industries due to their unique combination of chemical inertness, optical transparency, and mechanical stability. In the healthcare sector, these sensors are integral to the development of advanced biosensors for diagnostics, such as lab-on-a-chip devices and microfluidic platforms. Their biocompatibility and ability to support surface functionalization enable sensitive detection of biomarkers, pathogens, and other analytes in bodily fluids, facilitating rapid and accurate point-of-care testing Nature Publishing Group.

In the electronics industry, glass substrate sensors are pivotal in the fabrication of touch panels, display technologies, and thin-film transistors. Their excellent dielectric properties and dimensional stability make them ideal for supporting miniaturized electronic circuits and sensor arrays, contributing to the advancement of flexible and wearable electronics Corning Incorporated. Additionally, their optical clarity is essential for applications in photonic and optoelectronic devices, such as image sensors and optical filters.

Beyond healthcare and electronics, glass substrate sensors are increasingly utilized in environmental monitoring, food safety, and industrial process control. Their resistance to harsh chemicals and high temperatures allows for reliable operation in challenging environments, such as chemical plants and water treatment facilities. Furthermore, the adaptability of glass substrates to various sensor architectures—capacitive, resistive, or optical—broadens their applicability across emerging fields, including smart packaging and the Internet of Things (IoT) SCHOTT AG.

Performance Metrics: Sensitivity, Durability, and Transparency

The performance of glass substrate sensors is critically evaluated based on three primary metrics: sensitivity, durability, and transparency. Sensitivity refers to the sensor’s ability to detect minute changes in the target analyte or environmental condition. Glass substrates offer a smooth, chemically inert, and optically clear platform, which can enhance the signal-to-noise ratio and enable high-precision detection, especially in optical and biosensing applications. For instance, the low autofluorescence and high optical clarity of glass are advantageous in fluorescence-based biosensors, improving detection limits and accuracy (National Institute of Standards and Technology).

Durability is another essential metric, as sensors often operate in harsh or variable environments. Glass substrates are inherently resistant to corrosion, thermal shock, and many chemical agents, which extends the operational lifespan of the sensor. However, their brittleness can be a limitation, prompting research into reinforced or flexible glass composites to improve mechanical robustness without sacrificing performance (Corning Incorporated).

Transparency is a defining advantage of glass substrate sensors, particularly for applications requiring optical interrogation, such as photonic, plasmonic, or colorimetric sensors. High transparency across a broad spectral range allows for efficient light transmission and minimal signal loss, which is crucial for accurate optical measurements (Optica Publishing Group). The combination of these metrics—high sensitivity, robust durability, and excellent transparency—positions glass substrate sensors as a preferred choice in advanced sensing technologies for medical diagnostics, environmental monitoring, and industrial automation.

Recent Innovations and Emerging Trends

Recent innovations in glass substrate sensors are driving significant advancements in sensor technology, particularly in the fields of healthcare, environmental monitoring, and flexible electronics. One notable trend is the integration of micro- and nano-fabrication techniques, which enable the creation of highly sensitive and miniaturized sensor arrays on glass substrates. These advances allow for the detection of minute biological or chemical changes, making them ideal for point-of-care diagnostics and real-time environmental analysis. For example, the use of photolithography and laser patterning has improved the precision and scalability of sensor production, leading to more reliable and cost-effective devices Nature Publishing Group.

Another emerging trend is the development of flexible and transparent glass substrate sensors, which are increasingly being used in wearable devices and smart windows. Innovations in ultra-thin glass manufacturing have resulted in substrates that combine mechanical flexibility with high optical clarity and chemical stability. This has opened new possibilities for integrating sensors into curved or irregular surfaces without compromising performance Corning Incorporated.

Additionally, the incorporation of advanced materials such as graphene, metal oxides, and functional coatings onto glass substrates is enhancing sensor selectivity, sensitivity, and durability. These material innovations are enabling the detection of a broader range of analytes and improving sensor lifespans in harsh environments. As research continues, the convergence of glass substrate technology with wireless communication and data analytics is expected to further expand the application landscape of these sensors IEEE.

Challenges and Limitations in Adoption

Despite their promising attributes, the widespread adoption of glass substrate sensors faces several challenges and limitations. One primary concern is the inherent brittleness of glass, which can lead to mechanical failure under stress, impact, or during device fabrication processes. This fragility restricts the use of glass substrates in applications requiring high flexibility or robustness, such as wearable electronics or flexible medical devices. Additionally, the processing of glass often demands high temperatures and specialized equipment, increasing manufacturing complexity and cost compared to polymer or silicon alternatives (Corning Incorporated).

Another significant limitation is the integration of glass substrate sensors with other materials and components. Achieving reliable adhesion and electrical connectivity between glass and metals or semiconductors can be challenging, often necessitating additional surface treatments or intermediate layers. This can complicate device architecture and potentially impact sensor performance or longevity (SCHOTT AG). Furthermore, while glass offers excellent optical transparency and chemical resistance, its relatively low thermal conductivity may hinder heat dissipation in high-power or densely packed sensor arrays.

Finally, the cost of high-quality, defect-free glass substrates remains a barrier, particularly for large-area or high-volume applications. As a result, ongoing research focuses on developing tougher glass compositions, advanced fabrication techniques, and hybrid integration strategies to overcome these limitations and enable broader adoption of glass substrate sensors in diverse fields (AZoNano).

Future Outlook: Market Growth and Research Directions

The future outlook for glass substrate sensors is marked by robust market growth and dynamic research directions, driven by the expanding demand for high-performance, miniaturized, and reliable sensing technologies. The global market for glass substrate sensors is projected to experience significant growth, fueled by their increasing adoption in consumer electronics, automotive applications, healthcare diagnostics, and industrial automation. The unique properties of glass—such as chemical inertness, optical transparency, and thermal stability—make it an ideal platform for next-generation sensor devices, particularly in applications requiring high precision and durability.

Research is increasingly focused on enhancing the functionalization of glass surfaces to improve sensitivity, selectivity, and integration with microelectromechanical systems (MEMS) and lab-on-chip platforms. Innovations in thin-film deposition, surface modification, and nanostructuring are enabling the development of sensors with improved performance metrics and multifunctionality. Additionally, the integration of glass substrate sensors with wireless communication and data analytics is opening new avenues for smart sensing in the Internet of Things (IoT) ecosystem.

Emerging trends include the use of advanced glass materials, such as ultra-thin and flexible glass, to enable novel form factors and wearable sensor applications. Sustainability is also becoming a key research direction, with efforts to develop recyclable and energy-efficient sensor manufacturing processes. As the market continues to expand, collaborations between industry and academia are expected to accelerate the commercialization of innovative glass substrate sensor technologies, as highlighted by recent reports from MarketsandMarkets and IDTechEx.

Conclusion: The Impact of Glass Substrate Sensors on Modern Sensing

Glass substrate sensors have significantly influenced the evolution of modern sensing technologies, offering a unique combination of mechanical stability, chemical inertness, and optical transparency. These attributes have enabled the development of highly sensitive and reliable sensors for applications ranging from environmental monitoring to biomedical diagnostics. The inherent flatness and smoothness of glass substrates facilitate the precise deposition of functional materials, which is critical for the fabrication of miniaturized and integrated sensor devices. Furthermore, the compatibility of glass with advanced microfabrication techniques has accelerated the production of high-density sensor arrays, supporting the growing demand for multiplexed and real-time analysis in various fields.

The impact of glass substrate sensors is particularly evident in the advancement of optical and electrochemical sensing platforms. Their transparency allows for efficient light transmission, which is essential for optical biosensors and lab-on-a-chip devices. Additionally, the chemical resistance of glass ensures long-term stability and reproducibility, even in harsh environments. As a result, glass-based sensors have become indispensable in sectors such as healthcare, environmental science, and industrial process control. Ongoing research continues to expand their capabilities, integrating novel nanomaterials and surface modification strategies to enhance sensitivity and selectivity. The continued innovation in glass substrate sensor technology is poised to further transform modern sensing, enabling smarter, more responsive, and more accurate detection systems across diverse applications (Nature Publishing Group; Elsevier).

Sources & References

- National Institute of Standards and Technology

- Institute of Electrical and Electronics Engineers

- SCHOTT AG

- Carl Zeiss AG

- U.S. Department of Energy

- Nature Publishing Group

- AZoNano

- MarketsandMarkets

- IDTechEx